The work is based on a problem at the company NKT HV Cables AB, Karlskrona. NKT manufactures high-voltage cables which are pulled through complex ableways. The cables are stiff and difficult to bend, which results in them getting stuck in the cableways. In some parts of the factory, one cable will push another cable. This can also result in the cables getting stuck.

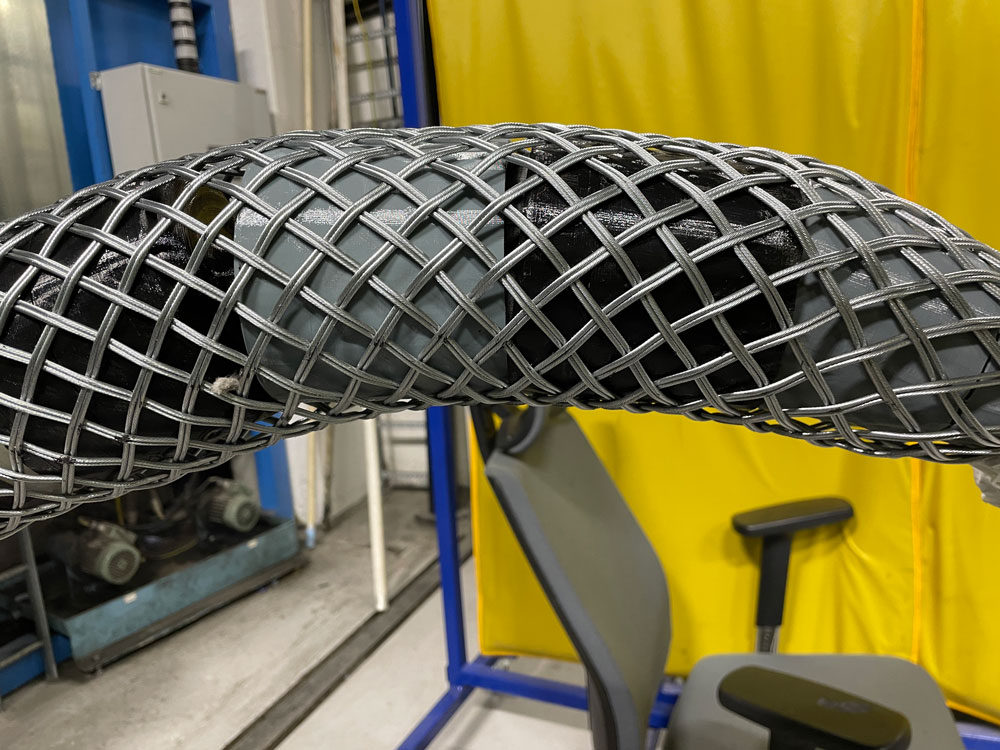

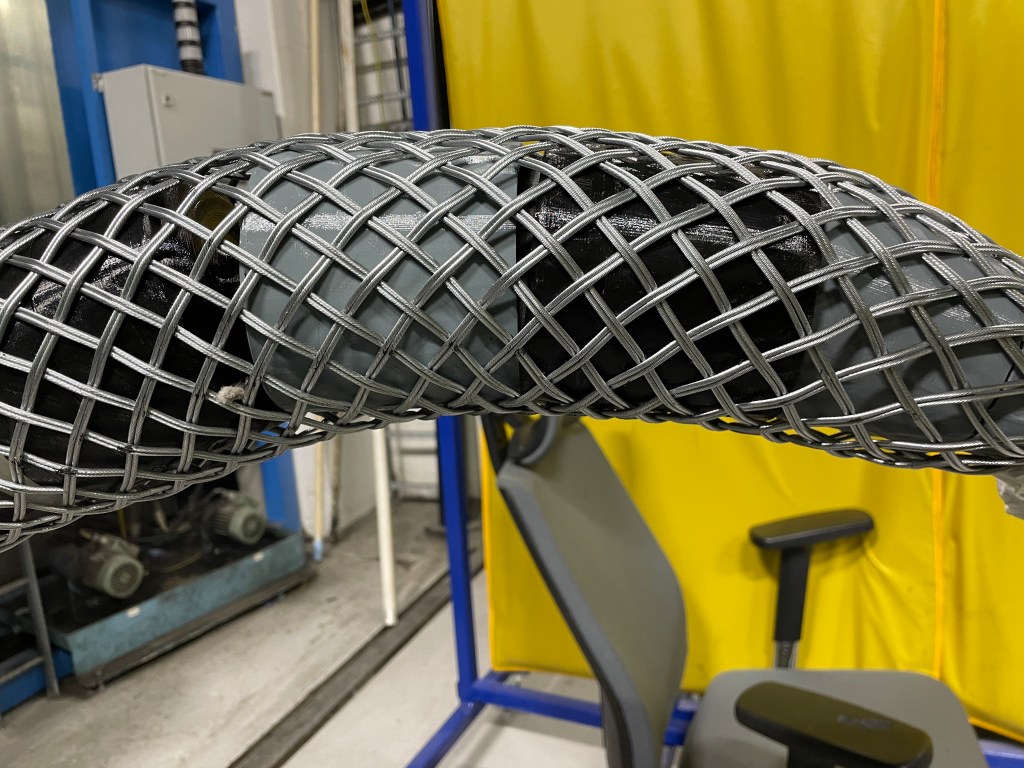

During the work, a prototype has been constructed which will prevent the cables from getting stuck in the cableways. This prototype is a bendable ball joint which is attached to the cable end. The ball joint bends the cable end into the tracks, which results in the cable following along. This construction was developed through literature studies, concept generation, concept screening, calculations, and testing.

FEM calculations were carried out and resulted in the ball joint being able to withstand the forces that occur when pulling forward. This was also verified by a test in an active production line. The result was that the ball joint bent the cable into the cableways and the functionality was confirmed.

For optimal function, a rigid connection between the cables is needed in order not to get stuck when the cable pushes the other. The delimitation is important in future development as this problem can persist without a rigid connection.

By David Callenryd & Anton Nilsson

Cooperation with