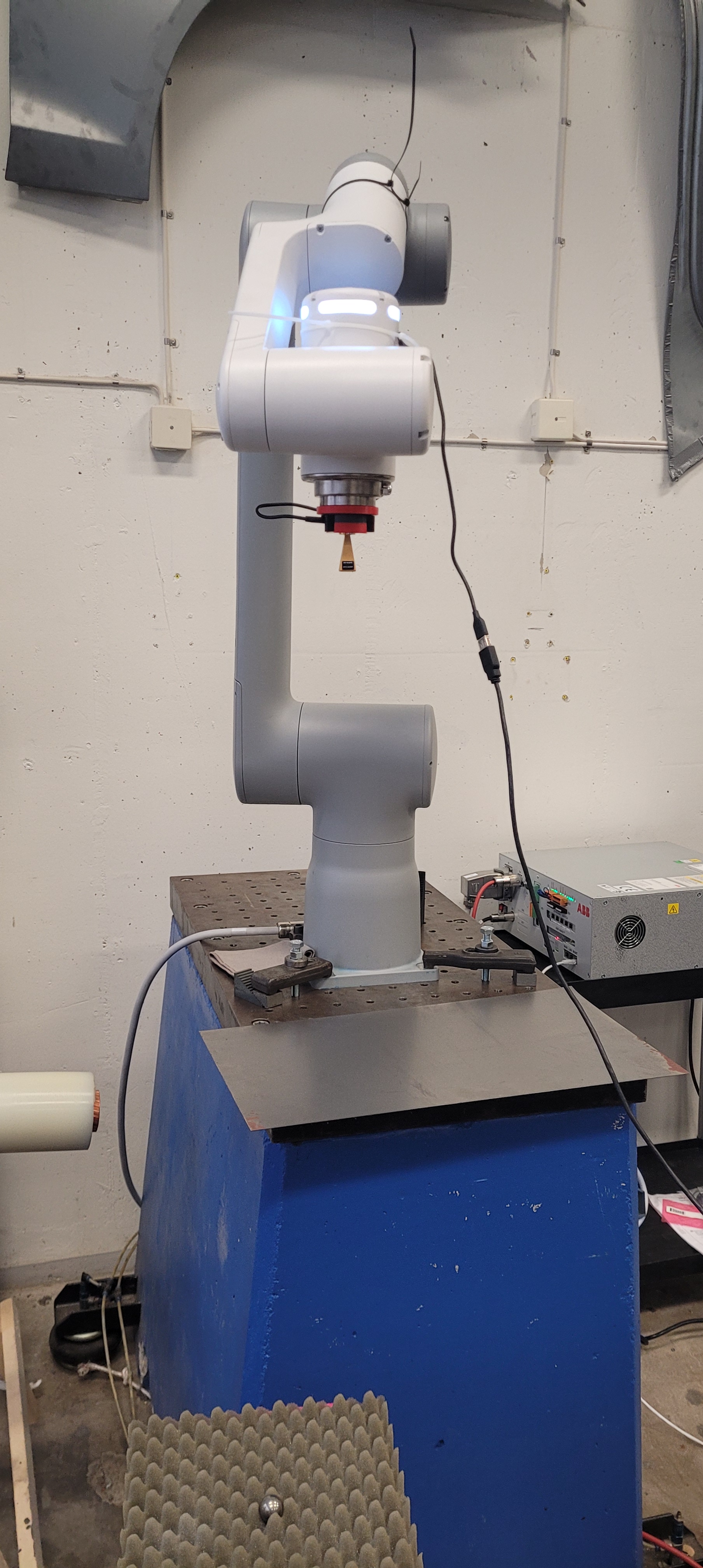

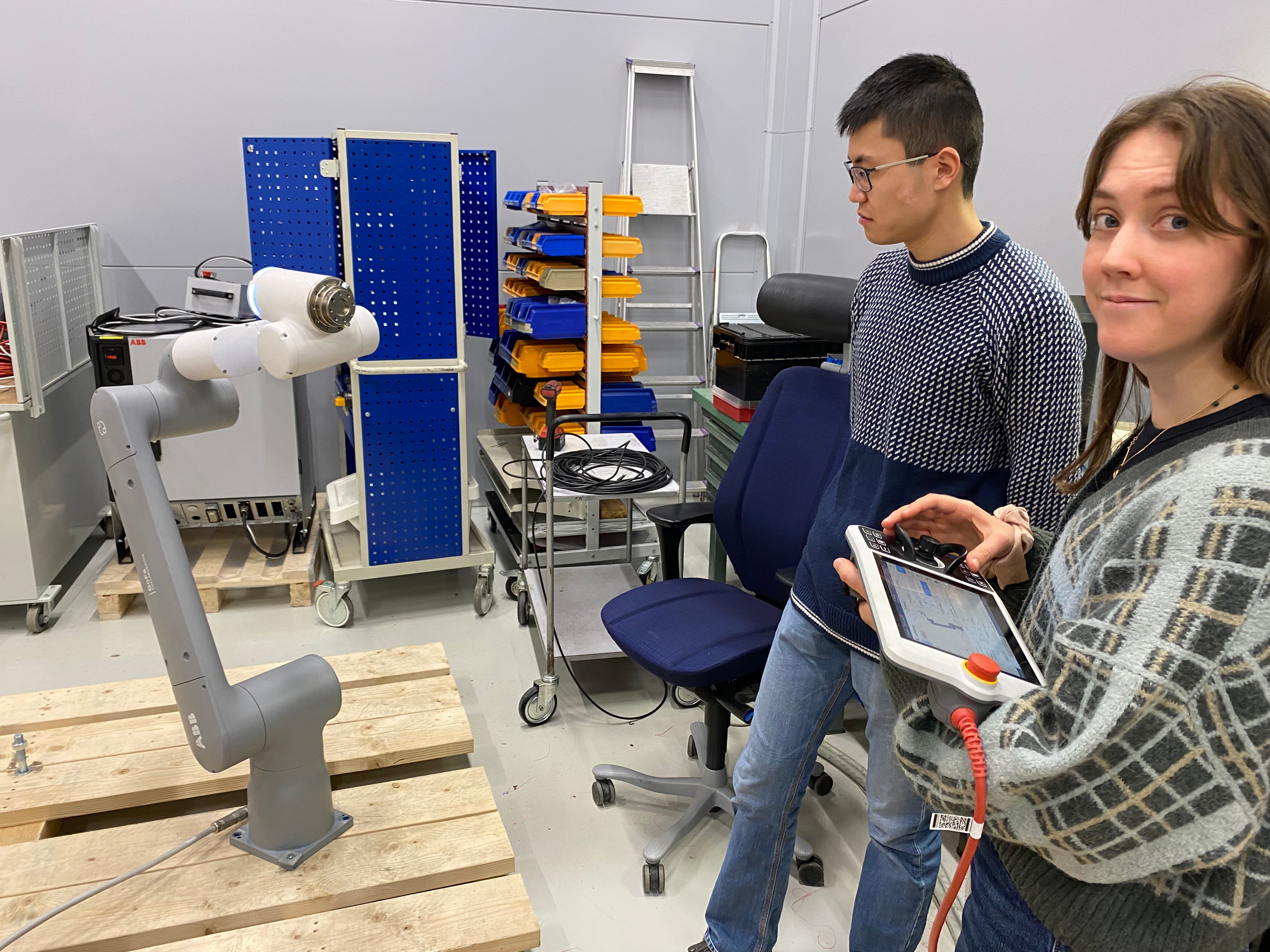

High-frequency radar imaging using Synthetic Aperture Radar (SAR) technology has significant potential for non-destructive testing and quality control in industrial applications, such as inspecting High Voltage Direct Current (HVDC) cables during manufacturing. This thesis develops and verifies a calibration procedure designed to accurately determine the Phase Centre (PC) of an FMCW radar antenna mounted on an industrial robotic arm, specifically the ABB GoFa CRB 15000.

Two calibration methods were developed and evaluated, an analytic approach and an empirical approach. The analytic method utilises geometric and trigonometric calculations based on distance measurements from rotations and alignments with known reference points. Simulations validated the theoretical accuracy, but experimental results demonstrated limitations due to measurement resolution constraints. Consequently, an empirical calibration method was developed, relying on comparative positional measurements by placing the radar in multiple known orientations and recording the corresponding distance readings. By analysing variations in these measurements, the relative offset of the radar’s phase centre from the robot’s reference point could be estimated. Experimental results indicated that this empirical method provided improved positional accuracy compared to the analytical method, identifying the PC position with a standard deviation of approximately 0.10 mm while similar approaches with external position measurement units and multiple robots achieved an accuracy of 0.02 mm.

The findings suggest that while the analytical method demands high measurement precision and is sensitive to measurement noise, the empirical method achieves closer alignment with the specified positional accuracy requirements. This research contributes a calibration procedure for integrating FMCW radar with industrial robots, enhancing the capabilities of SAR-based quality control methods for cable manufacturing and similar applications.

By Dong Jiang & Ninni Hammarström