Background: Saab, a Swedish defense and security firm, specializes in aerospace, defense, and maritime technologies. Challenges with customized mounts for naval systems hinder maintenance efficiency and cost-effectiveness. Developing standardized mounts could optimize operations, reduce costs, and improve readiness. Corrosion threatens structures, and reducing a vessel’s magnetic field signature enhances safety by lowering detection risk. Ship vibrations and forces require robust designs. Standardized solutions are crucial for cost savings in the packaging, maritime, and aerospace industries. Enclosures on vessels are placed on the ground for stability and mounted on the hull to optimize storage capacity.

Objectives: The thesis aims to translate customer needs into effective enclosure designs and develop adjustable mounting solutions for variable surface orientations, favoring standardization.

Methods: This study develops standardized mounting solutions for enclosures guided by user needs and iterative refinement. A Design Thinking approach fosters creative, user-centered solutions. Insights from maritime, aerospace, and transportation fields inform development. Stakeholder interviews prioritize user-centric approaches. Existing products are analyzed to identify areas for improvement. Concept selection relies on stakeholder input, salience models, and power-interest grids. Iterative design refinements ensure alignment with customer needs. Top-performing design concepts are prototyped and tested with FEA and FMEA, ensuring solutions meet objectives and expectations. Lastly, an iLogic program was created to improve the outfitting process further.

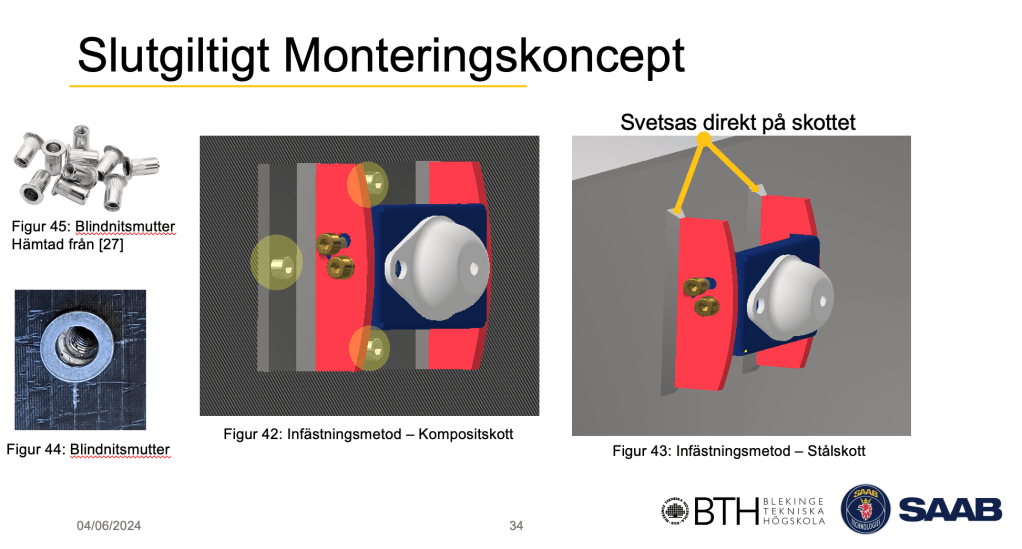

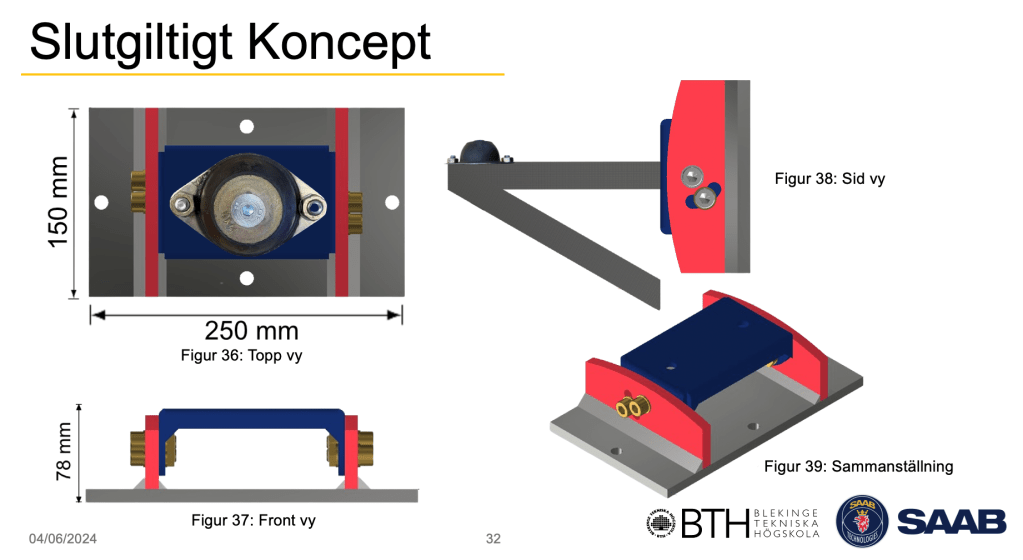

Results: Stakeholder demands, including load capacity, size constraints, corrosion resistance, and ease of installation, drive the development and standardization of enclosure mounting systems. Standardized systems like loading rails and mounting brackets are easy to maintain, while adjustable mounts offer flexibility and repairability. Stakeholder involvement significantly influences outcomes. Existing solutions are evaluated for feasibility and effectiveness. Idea generation and prototyping explored various concepts, ranked with a Pugh matrix. Design refinements focused on manoeuvrability, stability, and ease of installation, including adjustments to plate thickness, locking mechanisms, securing methods, and plate size. FMEA identified potential failure modes, leading to improvements. FEA validated structural strength and performance. Results highlight areas for optimization, enhancing confidence in product performance and reliability. Various mounting layouts were explored, and the ones passing testing were selected and implemented in iLogic.

Conclusion: This thesis outlines the development of standardized enclosure mounts for maritime environments, from demand identification to final concept development. The iterative process led to an adjustable angle mount with Novibra M10 shock mounts and AISI 316L stainless steel, addressing adaptability and reliability challenges. While real-life testing was limited, virtual simulations and expert consultations provided valuable insights. This work lays a foundation for further refinement and optimization, emphasizing stakeholder collaboration and iterative design for maritime applications. The product met initial requirements, validating the methodologies’ flexibility and robustness for various mounting scenarios, and can be used by Saab and other industries.

By Samuel Nilsson & Christian Elzouabi

Cooperation with