When aluminium profiles are manufactured, defects may arise, especially when the profiles are manufactured through extrusion. During the extrusion process, these defects occur on parts of the extruded material because of contaminates that need to be found.

The goal of the project is to examine two different types of methods that are suited for aluminium profiles in the category of non-destructive testing (NDT). The two different methods are non-linear ultrasonic methods called Higher Harmonics and Non-linear Wave Modulation Spectroscopy. The method that works should then also be implemented in a fixture. Of these two methods Higher Harmonics showed the most promising results by identifying which profile has defects and this method was also more appropriate to implement in a fixture.

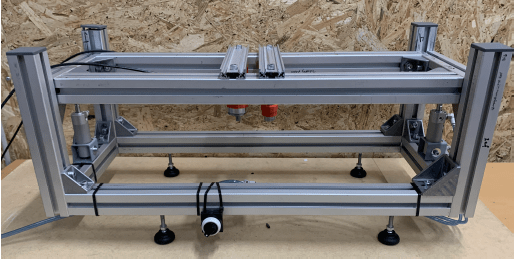

The Higher Harmonics method utilizes two transducers, one as an emitter to the system and another as a receiver. When the signal from the emitter passes through the non-linearities, which are the defects, and propagates to the receiver the signal can be inspected on an oscilloscope. The received signal is then transformed to the frequency domain and if there were defects harmonics should be generated. If there are many harmonics and the magnitude is high, defects are present. A fixture was also designed to work with the Higher Harmonics method using profile struts that are easy to connect to a framework.

The fixture worked by raising and lowering the two transducers which have been built into a probe. The emitting probe was connected to a signal generator and the receiving probe was connected to an oscilloscope. This measuring station did the measurement more consistent and accurate than before. The most interesting result that was found in the experiments was that localization of defects could be found.

By Robin Raymundsson and Viktor Svensson

Cooperation with