The main purpose of this project is to failsafe and raise the efficiency of the grinding process in a production environment by making it possible to detect blockages in initial stages inside the system.

The project has been defined to focus on solving the problems concerning the operational safety of the system since it´s mandatory to have a safe system to depend on when later optimizing it. With the focus set an iteration process begun where viable solutions where discussed, one of which suggested a process to reconstruct the intake which had the most problems out of the three. This solution was later in the process downvoted due to the wish of a more general solution where all the intakes could be monitored. Sensors was then determined to be the technology to be used.

The choice of sensor type was made by discussing the environment the solution should be applied in and the conditions of that certain environment which led to a list of requirements for the sensor. The aggravating conditions that are set in the system was the deciding factor that led to the choice of using a vacuum sensor. After further discussions, a specific sensor model could be chosen which fulfilled the needs and wishes that were set, including a LED display and a set-interval function.

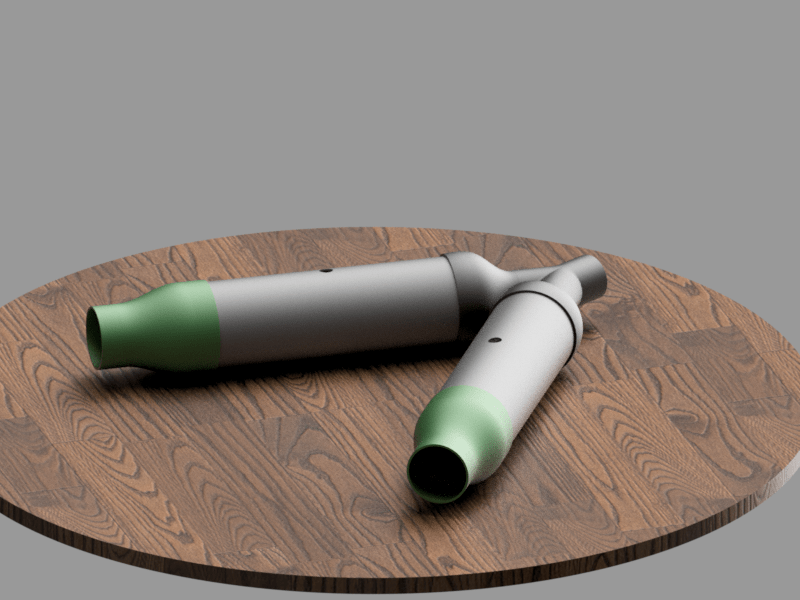

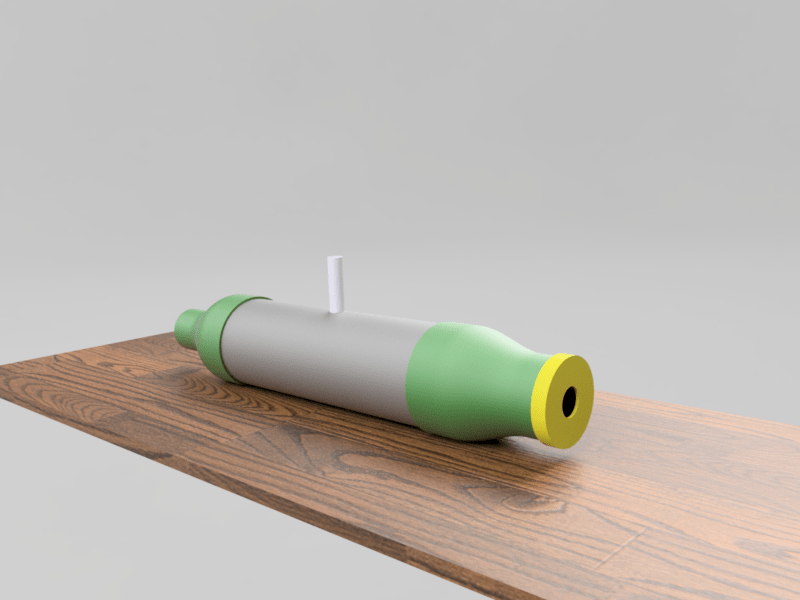

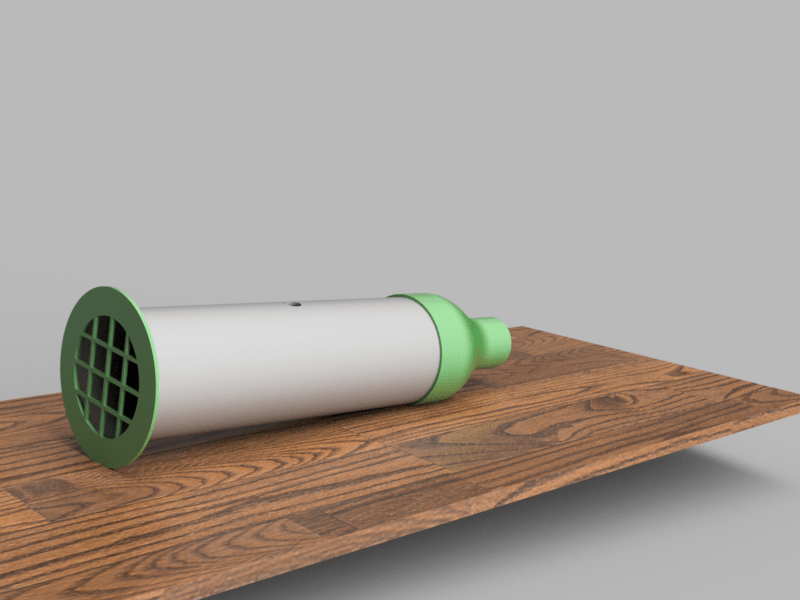

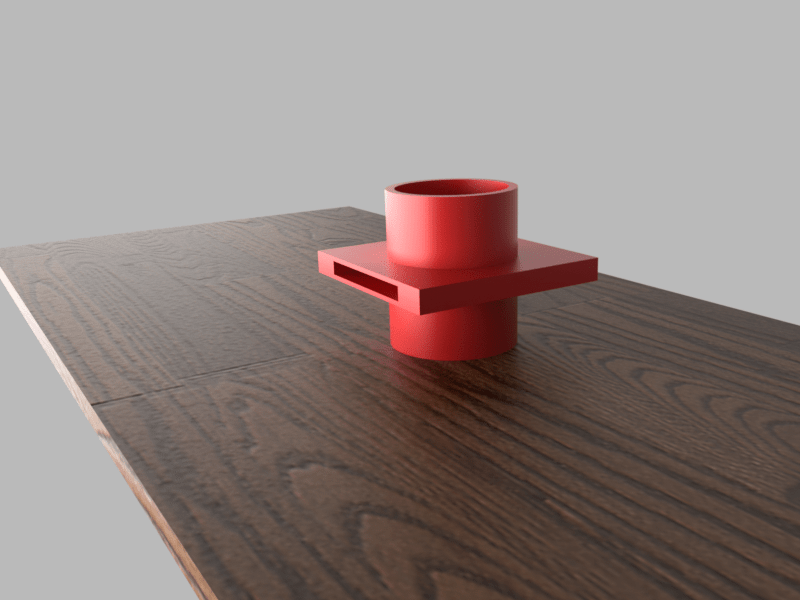

To reach a solution two main methods was evaluated, one of which used the theory of measuring the decrease of pressure inside the system when parts of an intake is blocked. This was evaluated in a testing environment using two different prototypes to evaluate the theory to later also be applied and tested in the production environment of the grinding machine. The second method to reach a solution used the theory of measuring pressure change passed a damper. Like the first test this method was evaluated in a testing environment using prototypes and later also, with the help of a 3D-printed damper tested in the production environment.

Both methods’ theory was verified by the prototype-tests. The solution using the pressure drop theory was although determined to not be effective in the production environment since the simulations of partly or fully blockages showed no changes in vacuum captured on the sensors. When measuring the difference of pressure through a damper the theory was verified and it was shown to be a working solution which would detect a blockage of 30-50% inside any of the intakes.

The results of the first test were not successful due to the complexity and size of the suction system where the many branches were shown to be the main reason for the inefficiency of the method. The information and results from this test were although shown to me much help when testing for pressure difference through a damper. The second test was shown to give a more successful result due to the better knowledge of the problem, the information gathered from the previous test and a better testing environment for the prototype testing.

The project has given the students and supervisors a greater understanding of the problem and how sensors could be used to solve those. From the two tested solutions one of the two is also considered to be a well-functioning and applicable method to use in a full-size solution to solve and further raise the efficiency of the process, with the need of only relatively small adaptions to the system.

By Petter Jonasson & Pontus Kallenberg

Cooperation with