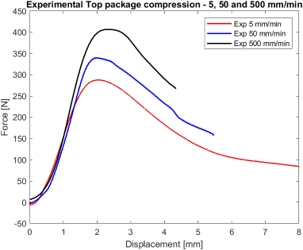

There is a high dependency on accurate finite element models in the packaging industry for concept selection, design and virtual validation of packages. One of the most used materials for these packages is High-Density Polyethylene (HDPE). This material is highly anisotropic, strain rate dependent and has different behavior in tension and compression.

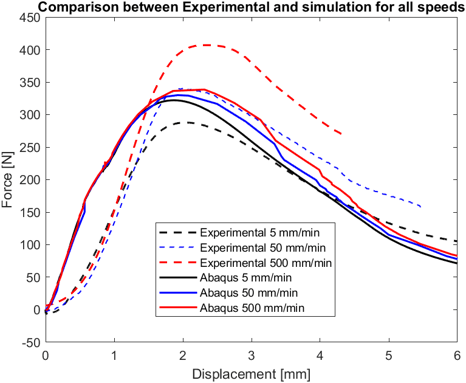

The objective of this thesis is to improve the existing constitutive model of HDPE through additional material characterization experiments and validate those models. For this purpose, strain rate dependencies of the material on elastic and hardening response are included in the constitutive model. In addition to that, the compressive behavior of HDPE was incorporated in the model as well.

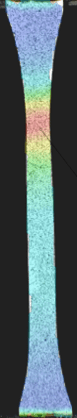

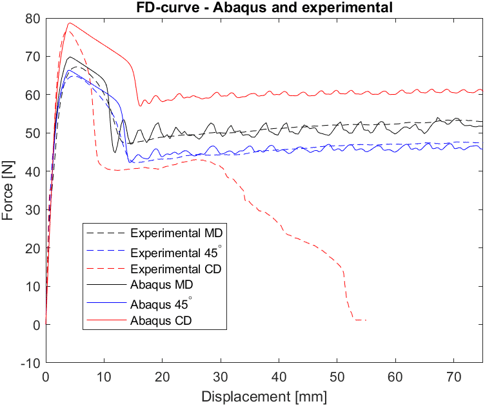

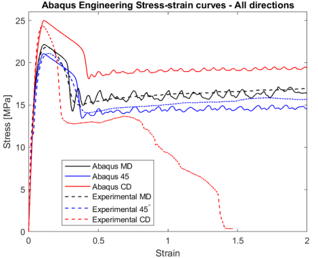

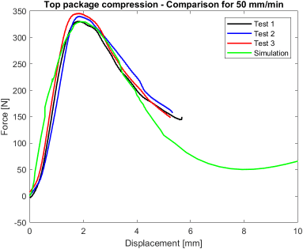

The anisotropy of HDPE was modeled using the Hill48 yield criterion which was characterized by performing multiple uniaxial tensile tests performed in the three directions: Machine Direction (MD), 45◦ and Cross Direction (CD). Validation was done on the coupon test and compression test on the package. The result displayed that the results from the physical test are comparable with the results obtained from the FE-models. From the tensile tests, the deformation of HDPE in MD and 45◦ was successfully captured and validated.

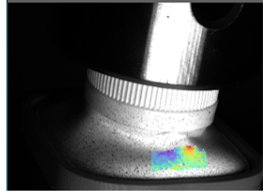

While for the CD direction, the deformation could be captured but not validated against FE-model. Also, the test results displayed that the material HDPE exhibits a significant degree of anisotropy. In conclusion, the project contributed knowledge and understanding of how a Tetra Pak package behaved during top load compression.

Abdullahi Abdi Hashi and Warsame Mohamed Ali

Cooperation with